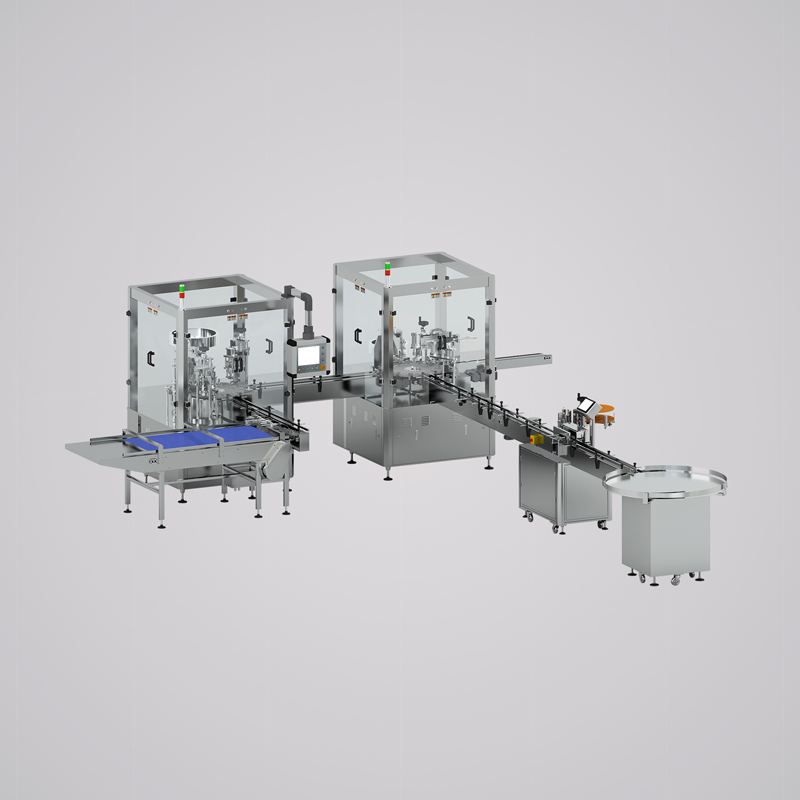

It is equipped with air cleaning for bottles, quantitative filling, negative pressure filling, spray cap feeder and detector, spray capping, ring feeder and detector, outer cap feeder and detector, unqualified rejected, and end product collecting

Moulds move in circles, easy to change bottles. By adjusting the moulds to make different bottle to same height level, reducing change parts.

The air bottle washing part extracts the air in the bottle body through the vacuum generator. The electromagnetic valve controls the air source to inflate the inside of the bottle body, sucking and blowing.

Stepping motor for quantitative filling, touch screen directly adjusts the filling amount and filling speed.

Negative pressure device is used to adjust the same liquid level, The negative pressure tank recycles excess materials.

The spray cap is automatically arranged through the vibration plate, and the robot automatically grabs the spray cap, completing the function of precapping the spray cap at the same time

Photoelectric check whether has finished spray cap feeding and capping.

Technical Parameters:

Capacity | 1200~1800 Pcs/h |

Bottle Diameter | ≤80mm |

Bottle height | ≤80mm |

Max filling volume | 250ml |

Power Supply | 380/220V(Optional) |

Compressed Air | 0.6~0.8Mpa |

Dimension | 5800(L)×3400(W)×2000(H) mm |